-

Máy đóng gói túi

-

Máy đóng gói hạt

-

Máy đóng gói chất lỏng

-

Máy đóng gói bột

-

Máy đóng gói Doypack mini

-

Máy đóng gói trà túi lọc

-

Máy đóng gói cà phê

-

máy đóng gói dọc

-

Máy đóng gói dòng chảy

-

Máy đóng gói túi đứng

-

Máy đóng gói chân không quay

-

Máy chiết rót

-

Máy đóng gói Doypack nằm ngang

-

Túi làm sẵn

-

Phụ kiện máy đóng gói

-

Máy đổ và nắp nắp

Máy đóng gói thực phẩm tự động đa năng cho các loại hạt, khoai tây chiên, bánh quy, kẹo, đậu phộng, đậu và gạo

| Nguồn gốc | Quảng Đông Trung Quốc |

|---|---|

| Hàng hiệu | ZCHONE PACK |

| Chứng nhận | ISO,CE |

| Số mô hình | ZC-8200 |

| Số lượng đặt hàng tối thiểu | 1SET |

| Giá bán | $18000 |

| chi tiết đóng gói | Bao bì vỏ gỗ xuất khẩu tiêu chuẩn |

| Thời gian giao hàng | 15 |

| Điều khoản thanh toán | L/C, D/A, D/P, T/T, Western Union, Moneygram |

| Khả năng cung cấp | 1/bộ/15 ngày |

Liên hệ với tôi để lấy mẫu miễn phí và phiếu giảm giá.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp hỗ trợ trực tuyến 24 giờ.

x| Kiểu | Máy đóng gói tự động | Tên sản phẩm | Máy đóng gói đa trạm thực phẩm |

|---|---|---|---|

| Kích thước (L*W*H) | L1900*W1400*H1450 | Trọng lượng (kg) | 1300 |

| Điện áp | 110V 220V 380V 50Hz/60Hz | Năng lực sản xuất | 20bag/phút, 50bag/phút, 30bag/phút |

| Làm nổi bật | Máy đóng gói thực phẩm hoàn toàn tự động,Máy đóng gói hạt dạng hạt,Máy đóng gói đa năng cho đồ ăn nhẹ |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

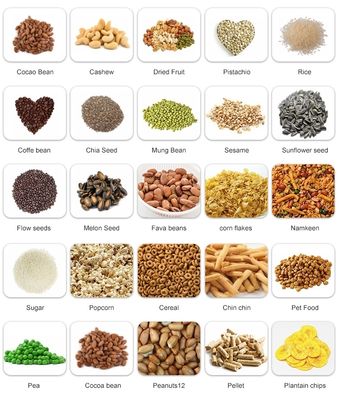

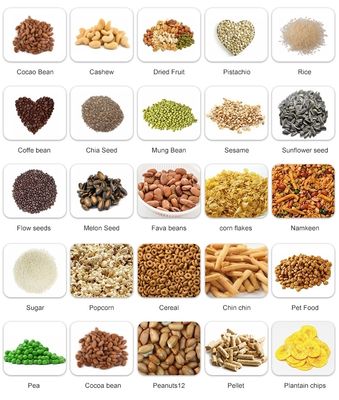

Máy đóng gói thực phẩm tự động đa chức năng cho các loại hạt, khoai tây chiên, bánh quy, kẹo, đậu phộng, đậu và gạo

"Máy đóng gói hạt trong túi" là một thiết bị chuyên dụng được sử dụng trong ngành chế biến thực phẩm.

I. Giới thiệu về Máy đóng gói hạt trong túi

Máy đóng gói hạt trong túi là một máy tự động hoặc bán tự động được thiết kế đặc biệt để đổ đầy và niêm phong các loại hạt khác nhau (như quả óc chó, hạnh nhân, hạt điều, hạt macadamia và đậu phộng) vào túi theo trọng lượng cài đặt trước. Nó cải thiện đáng kể hiệu quả sản xuất, đảm bảo chất lượng đóng gói và các tiêu chuẩn vệ sinh, đồng thời là một thiết bị cốt lõi cho các công ty chế biến hạt hiện đại.

II. Các loại chính

Dựa trên mức độ tự động hóa và định dạng đóng gói, các máy này chủ yếu được phân loại như sau:

1. Máy đóng gói túi đứng

Nguyên lý hoạt động: Đóng gói, đổ đầy và niêm phong tại chỗ được thực hiện bằng cách sử dụng màng cuộn. Bắt đầu với một cuộn màng đóng gói, một khuôn tạo hình nó thành một ống, niêm phong các cạnh theo chiều dọc. Một cơ chế niêm phong ngang sau đó niêm phong đáy, đổ đầy sản phẩm vào túi và cuối cùng niêm phong và cắt túi ở trên cùng để tạo thành một túi hoàn chỉnh.

Ưu điểm: Có nhiều kiểu đóng gói (như niêm phong mặt sau, niêm phong ba mặt và niêm phong bốn mặt), tiết kiệm không gian và thay đổi vật liệu linh hoạt.

Ứng dụng: Thích hợp cho việc đóng gói kích thước nhỏ (vài gam đến 1 kg) các loại hạt nhỏ và vừa (như đậu phộng, hạt dưa và hạnh nhân).

2. Máy đóng gói nạp túi

Nguyên lý hoạt động: Sử dụng các túi làm sẵn, máy tự động lấy túi ra, mở túi, đổ đầy vật liệu vào và sau đó niêm phong (ví dụ: niêm phong nhiệt, niêm phong bằng chỉ hoặc niêm phong bằng khóa kéo).

Ưu điểm: Cung cấp nhiều hình dạng túi hấp dẫn (như túi đứng, túi khóa kéo và túi có hình dạng tùy chỉnh), dễ dàng thực hiện việc nạp khí nitơ để bảo quản độ tươi và nhanh chóng.

Ứng dụng: Thích hợp để đóng gói nhiều kích cỡ và loại túi khác nhau, đặc biệt là đối với các sản phẩm hạt cao cấp yêu cầu nạp khí nitơ để bảo quản độ tươi.

3. Phân loại theo phương pháp cân

Cân một phễu: Cấu trúc đơn giản và chi phí thấp, nhưng tốc độ chậm và độ chính xác trung bình.

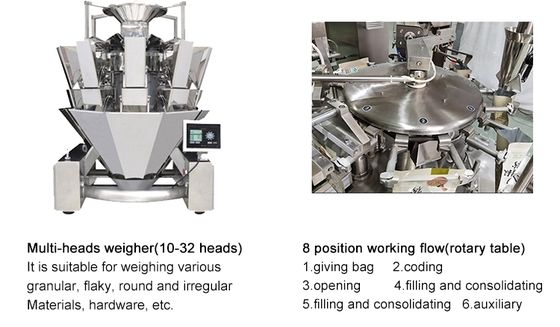

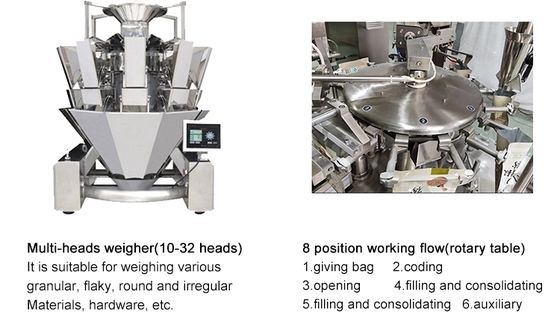

Cân kết hợp (cân kết hợp máy tính nhiều đầu): Bao gồm nhiều phễu cân. Máy tính tính toán trọng lượng của nhiều phễu và kết hợp chúng để có được sự kết hợp gần nhất với trọng lượng mục tiêu để đổ đầy.

Ưu điểm: Độ chính xác cực cao (lên đến ±0,1-1 gam) và tốc độ cao khiến nó trở thành lựa chọn chủ đạo và có độ chính xác cao để đóng gói hạt.

Áp dụng cho: Tất cả các dây chuyền đóng gói tự động có yêu cầu về trọng lượng nghiêm ngặt.

III. Các thành phần cốt lõi

Một máy đóng gói hạt trong túi hoàn chỉnh thường bao gồm các hệ thống sau:

Hệ thống nạp: Hạt được vận chuyển đến phễu chứa của máy đóng gói thông qua thang máy, tấm rung hoặc băng tải.

Hệ thống cân: Thành phần cốt lõi, chẳng hạn như cân kết hợp hoặc cân một phễu, chịu trách nhiệm đo chính xác trọng lượng của mỗi túi.

Hệ thống tạo hình và đổ đầy túi (Máy dọc) hoặc Hệ thống mở túi (Bộ nạp túi): Hoàn thành việc tạo hình hoặc chuẩn bị túi.

Hệ thống nạp nitơ (Tùy chọn): Trước khi niêm phong, túi được hút hết không khí và nạp đầy nitơ để kéo dài thời hạn sử dụng của hạt và ngăn chặn quá trình oxy hóa dầu.

Hệ thống niêm phong nhiệt: Một bộ phận làm nóng niêm phong miệng túi.

Hệ thống mã hóa: In thông tin như ngày sản xuất và số lô trên túi.

Hệ thống điều khiển: PLC (Bộ điều khiển logic lập trình) và giao diện người-máy màn hình cảm ứng được sử dụng để cài đặt thông số, điều khiển toàn bộ quy trình và theo dõi trạng thái hoạt động.

IV. Tóm tắt và Khuyến nghị

Doanh nghiệp nhỏ/Thương hiệu khởi nghiệp: Bắt đầu với máy đóng gói bán tự động (đặt túi thủ công, máy cân và đổ đầy) hoặc máy đóng gói cân kết hợp dọc cơ bản. Chúng cung cấp khoản đầu tư thấp và tính linh hoạt cao.

Doanh nghiệp vừa và lớn hơn: Chúng tôi khuyên dùng máy đóng gói nạp túi tự động hoàn toàn hoặc máy đóng gói dọc tốc độ cao, được trang bị cân kết hợp và khả năng nạp nitơ, để đáp ứng nhu cầu sản xuất số lượng lớn, chất lượng cao và thời hạn sử dụng lâu dài.

Dòng sản phẩm cao cấp: Máy đóng gói nạp nitơ là lựa chọn ưu tiên, cung cấp vẻ ngoài đóng gói đẹp nhất và bảo quản độ tươi tối ưu.

Thông số kỹ thuật máy:

| Mục | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Đóng góitốc độ | TỐI ĐA 60 túi/phút, tùy thuộc vào chất lượng của màng đóng gói, vật liệu đóng gói, trọng lượng đóng gói, v.v. | ||

| Kích thước túi | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Loại túi | Túi làm sẵn, túi đứng, túi niêm phong bốn mặt, túi niêm phong ba mặt túi, túi có hình dạng đặc biệt | ||

| Phạm vi cân | 10g-1kg | 10g-2kg | 10g-3kg |

|

Đo lường độ chính xác |

*≤±0,5~1%, tùy thuộc vào thiết bị đo lường & vật liệu. | ||

| Chiều rộng túi tối đa | 200mm | 250mm |

300mm |

| Khí tiêu thụ | 0.8Mpa 0.3m3/phút (Do người dùng cung cấp) | ||

| Tổng Bột/Điện áp | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Máy nén khí | Không dưới 1CBM | ||

| Kích thước | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Trọng lượng máy | 1300kg | 1400kg | 1500kg |

| Quy trình làm việc | Cho túi→Mã hóa→Mở túi (hoặc Mở túi khóa kéo)→Đổ đầy→ Phụ trợ→Xả→Niêm phong nhiệt→Tạo hình và xuất sản phẩm. | ||

| Phạm vi áp dụng | Loại hạt: bột ngọt tinh thể, thuốc dạng hạt, viên nang, hạt giống, hóa chất, đường, tinh chất gà, hạt dưa, hạt, thuốc trừ sâu, phân bón, v.v. | ||

(Chúng tôi có thể cung cấp cho bạn các dịch vụ tùy chỉnh độc quyền theo nhu cầu của bạn!)

![]()

![]()

![]()

![]()