-

Máy đóng gói túi

-

Máy đóng gói hạt

-

Máy đóng gói chất lỏng

-

Máy đóng gói bột

-

Máy đóng gói Doypack mini

-

Máy đóng gói trà túi lọc

-

Máy đóng gói cà phê

-

máy đóng gói dọc

-

Máy đóng gói dòng chảy

-

Máy đóng gói túi đứng

-

Máy đóng gói chân không quay

-

Máy chiết rót

-

Máy đóng gói Doypack nằm ngang

-

Túi làm sẵn

-

Phụ kiện máy đóng gói

-

Máy đổ và nắp nắp

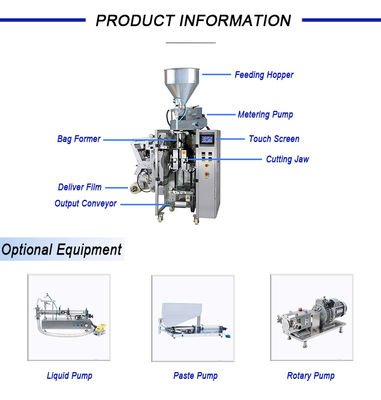

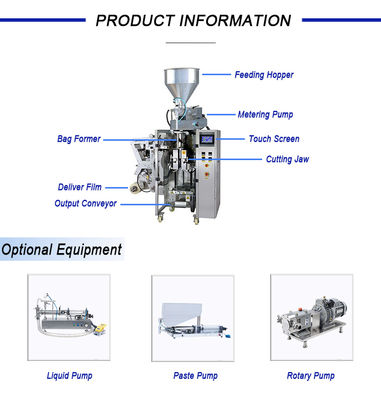

Máy đóng gói chất lỏng dạng sệt theo chiều dọc với túi bốn cạnh niêm phong bằng giấy/màng nhựa Tự động chiết rót & hàn kín 220V/380V

| Nguồn gốc | Quảng Đông Trung Quốc |

|---|---|

| Hàng hiệu | ZCHONE PACK |

| Chứng nhận | ISO,CE |

| Số mô hình | ZC-VS32 |

| Số lượng đặt hàng tối thiểu | 1 bộ |

| Giá bán | $18000 |

| chi tiết đóng gói | Bao bì vỏ gỗ xuất khẩu tiêu chuẩn |

| Thời gian giao hàng | 15 |

| Điều khoản thanh toán | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Khả năng cung cấp | 1/bộ/15 ngày |

Liên hệ với tôi để lấy mẫu miễn phí và phiếu giảm giá.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp hỗ trợ trực tuyến 24 giờ.

x| Kiểu | Máy đóng gói đa chức năng | Bảo hành | 12 tháng |

|---|---|---|---|

| Ứng dụng | Thực phẩm, Hóa chất, Hàng hóa, Y tế, Máy móc & Phần cứng | Loại bao bì | túi, túi |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Máy đóng gói bột nhão lỏng dạng đứng với túi niêm phong bốn cạnh bằng giấy/màng nhựa tự động chiết rót & hàn 220V/380V

Máy đóng gói đứng cho bơ là một thiết bị đóng gói tự động được thiết kế đặc biệt cho các loại thực phẩm sệt và bán rắn như bơ, bơ thực vật và phô mai. Nó sử dụng phương pháp "tạo túi theo chiều dọc", có nghĩa là từ cuộn màng ban đầu, máy trực tiếp hoàn thành một loạt các hành động bao gồm tạo túi, chiết rót, niêm phong và cắt, cuối cùng xuất ra các sản phẩm hoàn thiện được đóng gói riêng lẻ.

I. Nguyên lý hoạt động

1. Tạo túi: Các cuộn màng đóng gói (chẳng hạn như màng composite nhôm hoặc màng composite nhiều lớp) được gắn trên máy. Màng đi qua thiết bị căng và con lăn dẫn hướng và được kéo vào bộ phận tạo hình. Bộ phận tạo hình cuộn màng phẳng thành hình trụ.

2. Niêm phong dọc: Các cạnh của màng được niêm phong dọc bằng thiết bị hàn nhiệt, tạo thành một túi hình trụ liên tục.

3. Niêm phong và cắt ngang: Một cặp hàm niêm phong ngang đồng thời hàn nhiệt cả hai đầu của túi hình trụ. Vết niêm phong ngang phía trên đóng vai trò là niêm phong trên cùng của túi hiện tại và vết niêm phong ngang phía dưới đóng vai trò là niêm phong dưới cùng của túi tiếp theo. Đồng thời với việc niêm phong ngang, một dao cắt tách các túi trước và sau giữa hai vết niêm phong.

4. Chiết rót: Trong khoảng thời gian giữa các chuyển động của cơ chế niêm phong ngang, một lượng bơ đã đo được được bơm vào các túi đã được niêm phong đáy thông qua vòi chiết rót phía trên. Bơm piston thường được sử dụng để chiết rót, làm cho nó lý tưởng để xử lý các vật liệu có độ nhớt cao.

5. Đầu ra: Sau khi chiết rót và niêm phong trên cùng, các túi được cắt và rơi vào băng tải hoặc giỏ thu gom.

Toàn bộ quá trình được điều khiển chính xác bởi PLC (Bộ điều khiển logic khả trình) và hệ thống servo, đạt được sản xuất tự động, liên tục, tốc độ cao.

II. Các tính năng chính

1. Hiệu quả cao: Mức độ tự động hóa cao; tốc độ đóng gói có thể đạt tới hàng chục đến hàng trăm túi mỗi phút, vượt xa việc đóng gói thủ công.

2. Độ chính xác cao: Bơm piston chính xác hoặc chiết rót bằng servo đảm bảo trọng lượng nhất quán trong mỗi túi bơ, đáp ứng các tiêu chuẩn đo lường quốc gia.

3. Bao bì đẹp mắt: Các đường niêm phong chắc chắn và phẳng, hình dạng túi đồng đều, nâng cao chất lượng sản phẩm.

4. Giảm ô nhiễm: Quá trình tự động hoàn toàn làm giảm đáng kể sự tiếp xúc giữa người và vật liệu, đáp ứng các tiêu chuẩn vệ sinh và an toàn thực phẩm (chẳng hạn như GMP, HACCP).

5. Tính linh hoạt: Bằng cách thay đổi các thiết bị tạo hình và vòi chiết rót khác nhau, nó có thể thích ứng với các túi đóng gói có kích thước và hình dạng khác nhau (chẳng hạn như niêm phong mặt sau, niêm phong ba mặt và niêm phong bốn mặt).

6. Tiết kiệm nhân công: Một người thường được yêu cầu vận hành một máy, chịu trách nhiệm cho việc nạp và giám sát, giảm đáng kể chi phí lao động.

7. Khả năng thích ứng vật liệu rộng: Ngoài bơ, với một vài điều chỉnh nhỏ, nó cũng có thể được sử dụng để đóng gói mứt, bột nhão, mật ong, bột đậu và các sản phẩm khác có độ nhớt tương tự.

III. Sản phẩm và ngành công nghiệp áp dụng

1. Sản phẩm chính: Bơ, bơ thực vật, phô mai, kem phô mai, cô đặc kem, kem đánh răng, thuốc mỡ, v.v.

2. Ngành công nghiệp chính: Ngành công nghiệp sữa, ngành công nghiệp bánh, nhà máy chế biến thực phẩm, chuỗi cung ứng ăn uống, ngành công nghiệp hóa chất và dược phẩm.

Thông số kỹ thuật máy:

|

Tốc độ đóng gói |

5 - 40 túi / phút |

| Kích thước túi (mm) | L100 - 250, W30 - 160 |

| Chiều rộng màng tối đa (mm) | 320 |

| Độ dày túi (mm) | 0.04 - 0.09 |

| Phạm vi chiết rót | 10 - 100g |

| Vật liệu túi | BOPP / CPP, PET / AL / PE, v.v. |

| Khí nén | 0.8MPa, 0.5m3/phút |

| Điện | 4.5KW |

| Điện áp | 220v 50/60Hz |

| Kích thước thiết bị (mm) | 1350*1120*1250 |

| Trọng lượng thiết bị (KG) | 500 |

| Loại túi | Túi niêm phong 4 mặt (Tùy chọn: túi niêm phong 3 mặt) |

(Chúng tôi có thể cung cấp cho bạn các dịch vụ tùy chỉnh độc quyền theo nhu cầu của bạn!)

![]()

![]()

![]()

Ứng dụng:Nước ép, mứt, gói nước sốt, tương cà, nước xốt salad, nước sốt trái cây, dầu gội đầu, xì dầu, v.v.

Dịch vụ sau bán hàng:

1. Cung cấp hướng dẫn sử dụng/video để cài đặt, điều chỉnh, thiết lập và bảo trì máy để bạn sử dụng.

2. Nếu vấn đề không thể giải quyết, có thể liên lạc qua điện thoại 24 giờ hoặc giao tiếp trực tuyến trực tiếp.

3. Các kỹ sư và kỹ sư kỹ thuật của SUNCHON có thể cung cấp dịch vụ máy tại quốc gia của bạn.

4. Toàn bộ máy được bảo hành 1 năm. Trong thời gian bảo hành, các bộ phận không bị hư hỏng do con người gây ra. Chúng tôi sẽ thay thế bằng một cái mới cho bạn miễn phí. Bảo hành sẽ bắt đầu sau khi máy được gửi đi và chúng tôi nhận được vận đơn.

5. Chúng tôi sẽ cung cấp hỗ trợ kỹ thuật trọn đời và cung cấp phụ kiện liên tục.